Browse Items (1557 total)

Sort by:

-

"Picknick - Meridian. Xmas. Smokies. Grand Canyon - Fire (1964)."

The label on the inside of the can notes, "Picnic 1955. Western trip 1964."

-

"1967."

Home movies of the Burwell family as they settled into their new home in Huntsville. There is some vacation footage but the majority of the film is of mid-century Huntsville and Chattanooga.

Beach scenes [11:55]

Cattle and rural scenes [09:57]

Chores [08:02]

Clay shooting [09:13]

Dog [00:01, 4:38, 7:46, 18:01, 20:01, 20:51]

Fly [21:33]

Homes [02:28, 03:10]

Snow [03:52, 06:46]

Lookout Mountain Hotel [09:07] -

"Master plan for documentation management and use."

The objective of this study is to describe a comprehensive plan for the development and full utilization of methods and means to be employed in the years prior to 1976 for the effective acquisition, collection, storage, retrieval, distribution, and use of engineering documentation. Because of the violently changing state of the art of data acquisition, storage, and retrieval the description of the plan does not embrace the details of a total decade of phased change. Rather it describes actions that can and should be taken in the relatively near future, and proposes a continuing series of later studies to keep this plan current for the full decade. -

"Corrosion problems associated with the Saturn space vehicles."

Corrosion problems associated with space vehicles, in general, are discussed as contrasted to those problems experienced with structures in an earth atmosphere. Primary emphasis is placed on structural alloys in this discussion, although some corrosion failures experienced in various mechanical components are described. General corrosion prevention measures are indicated, and solutions to specific corrosion failures described. Major failures experienced have been attributed to stress corrosion cracking, rather than general or galvanic type corrosion. Most such failures have occurred with only five different materials: three aluminum alloys - 7075-T6, 7079-T6, and 2024-T6; and two precipitation hardening stainless steels - 17-7PH and AM 355. Corrective actions were different in each case, but involved either a complete change to another material, a change to a different temper of the same alloy, or a modification of the heat treatment and/or general processing techniques. General conclusions are that the types of failures described could be avoided by: a more suitable selection of alloys in the initial design, a realistic review of the environments that could be encountered in the service lifetime of the component, lowering stresses, improving process controls, and effecting better familiarization of design personnel with the with the overall stress corrosion problem in an effort to reduce human error.; Preprint 18e.; Materials for re-entry and spacecraft systems - spacecraft materials.; Materials Conference, Philadelphia, Pennsylvania, March 31 - April 4, 1968. -

"Conditions contributing to stress corrosion [list] photograph."

8 x 10 inch black and white photograph. A photograph of a list of things contributing to stress corrosion. Referenced by "Materials in Space Exploration." Is part of envelope containing photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

"A comparison of four control systems proposed for Saturn V launch vehicles."

Presented are the results of a study comparing four proposed control systems for the first stage flight of Saturn V launch vehicles. The primary basis of comparison is the effect on structural loads, using the bending moments at three stations as load indicators. Two of the systems sense only the vehicle attitude and attitude rate, while the other two systems also sense the lateral acceleration. A yaw plane wind response analysis, including rigid body translation, rigid body rotation, four bending modes, five slosh modes, and a non ideal control system, was performed. The winds used in the study were the Marshall synthetic profile and three selected Jimsphere-measured real wind profiles. Load relief obtained from the addition of accelerometer feedback in the control loop amounted to about 10 percent at maximum bending moment station. In view of predicted structural capabilities of the vehicle, this reduction in loads was not considered sufficient to offset the added complexity and the slight reduction in rigid body stability . -

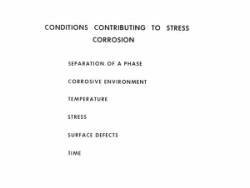

"Common bulkhead drawing."

8 x 10 inch black and white photograph; This is a cutaway drawing of the bulkhead with information about the LH2 tank skin, insulation, Aft LOX bulkhead, 2014-T6 alum skin and fiberglass core. Part of an envelope with photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

"The development of the Saturn system safety program."

This paper describes the major highlights or milestones passed in the development of a System Safety Program at MSFC since early 1967. it discusses accomplishments, problems resolved, and decisions made for Apollo Saturn vehicles AS-501 and AS-502, and projects that are to be accomplished on future Saturn vehicles. -

"A description of the ST-124M inertial stabilized platform and its application to the Saturn V launch vehicle."

This report is a description of the ST-124M inertial stabilized platform system and its application to the Saturn V launch vehicle. It is a summary report providing the system concept, and not a theoretical presentation. Mathematical equations were included only where necessary to describe the equipment; however, the detailed derivations supporting these equations were not presented since this was not the theme of the paper. -

"Decision Procedure for Minimizing Costs of Calibrating Liquid Rocket Engines."

Prior to acceptance of a liquid rocket engine for use in Saturn vehicles, the average thrust of two consecutive tests without an intervening calibration must satisfy specification requirements. The contractor may recalibrate after the first and subsequent tests if he so chooses, based upon decision limits, until the above requirement is met. -

"A decade of space progress, 1958 to 1968: General Electric Missile and Space Division offers a pictorial tribute to the National Aeronautics and Space Administration."

Excerpt from G.E. Challenge, Fall (Sept.) 1968, pages 13 to 25. -

"D5-13197 manufacturing plan: AAP."

This Manufacturing plan is prepared in response to the Apollo Applications Program request for proposal No. 1.1.; PURPOSE: The purpose of this document is to present a Boeing plan for the manufacturing effort required to provide hardware and support for the installation and checkout of Experiment Packages and related equipment in the Apollo Systems Modules. -

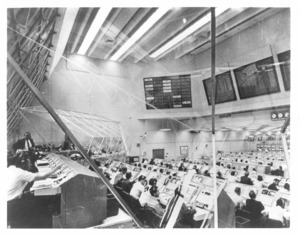

"Electrical support equipment" (ESE) [photograph].

8 x 10 inch black and white photograph. A photograph of a workspace. -

"Dynamic Problems in Launch Vehicles and Spacecraft."

Addresses improving spacecraft safety by resolving various known dynamic problems. -

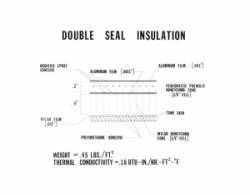

Double seal insulation [drawing] photograph.

8 x 10 inch black and white photograph.; Drawing contains information about the modified epoxy adhesive, aluminum film, mylar film, perforated phenolic honeycomb core, tank skin, mylar honeycomb core, polyurethane adhesive, weight and thermal conductivity.; Photo negative no. 651746 M-268. -

"Digital Simulation of an Aerospace Vehicle."

The rapid development of computer technology and the creation of new engineering oriented languages has established that general purpose digital computers are now extremely suitable to perform simulation of large scale physical systems. With Aerospace Vehicle Simulation (AVS), an effort has been undertaken at MSFC to simulate continuous and discrete dynamics of an aerospace vehicle and its ground support equipment on a large digital computer. This simulation produces a copy of the physical vehicle configuration and its functions in the form of a large scale mathematical model in the computer. AVS will be an essential part of an integrated information system which can be used by several laboratories and offices at MSFC for the design, checkout, test, and management of aerospace vehicles. -

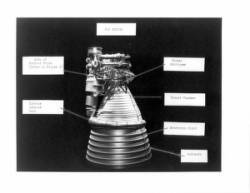

F-1 engine photograph.

8 x 10 inch black and white photograph. Engine parts are labeled. -

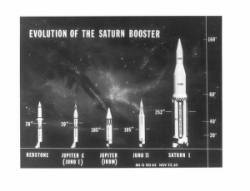

"Evolution of the Saturn Booster."

8 x 10 inch Black & White photograph. MS-G 103-63 Nov. 22, 63 is on the photograph. Displays the evolution of space-rocket designs side-by-side. -

"Goddard patents: notes from von Braun to Slattery."

Archive copy is a poor photocopy.; Handwritten in ink is: Ref: Goddard Patents (See D. Akens for final draft of letter). -

"Forecasting future military missions and their technological demands."

Archive copy is a poor photocopy.; Article is from Defense Industry Bulletin, October 1959, pages 21 to 24. -

"Instrument Unit Program Review : Saturn Instrument Unit."

Handwritten names and phone numbers on the first page. Apollo / Saturn Team. -

"The instrumentation of space vehicle in connection with the successful Saturn flight tests."

Presented on September 21, 1962, at the Eleventh Tagung Der Deutchen Raketen - Gesellschaft, Koblenz, West Germany. Instrumentation sf the Saturn space vehicle represents a considerable effort during the development phase, for proper design evaluatian of this new configuration, its propulsion system, and its structure and control characteristics, an unprecedented number of measurements are required to be carried onboard and to be recovered, These measurements are expected to work properly and to furnish the design engineer with information that is not available by ground testing, -

"The impact of manufacturing on design as related to accessibility."

The purpose of this paper is to emphasize the need for accessibility in the assembly and maintenance of spacecraft. This is especially pertinent because accessibility to subsystems for replacement, repair, and maintenance has proven to be one of the more costly phases of preflight preparation. The most successful programs in this day and age have been when the design and manufacturing engineers work side by side around a mockup where solutions to the problems can be visually seen and solved, keeping in mind the assembly as related to accessibility. Therefore, it will be shown that in order to overcome the difficulties, designers should adapt a hard, fast ground rule that each unit must be accessible and individually removable without disturbing the other units.; Aeronautic and Space Engineering and Manufacturing Meeting, Los Angeles, Calif. Oct. 7 - 11, 1968. -

Letter to Mr. David L. Christensen.

Letter from C.A. Perkins to David L. Christensen regarding a request for information regarding cryogenic pump and motor development -

Letter to Honorable James E. Webb, Administrator, National Aeronautics and Space Administration from W. K. Wilson, Jr.

Letter to James Webb from W. K. Wilson regarding one of his studies. -

Letter to the Honorable James E. Webb, Administrator, National Aeronautics and Space Administration from Kurt R. Stehling.

A letter to Jame E. Webb proposing that the first LEM that lands on the moon to be named after President Kennedy." -

"List of Saturn-Apollo Suppliers of Critical Hardware."

A list of critical hardware from Saturn-Apollo Suppliers. -

"Master plan for documentation management and use."

Prepared for National Aeronautics and Space Administration, George C. Marshall Space Flight Center, Huntsville, Alabama. Accepted by V.C. Sorensen, Chief, Management Services Office. Management Services Project, RCA; SUMMARY: The objective of this study is to describe a comprehensive plan for the development and full utilization of methods and means to be employed in the years prior to 1976 for the effective acquisition, collection, storage, retrieval, distribution, and use of engineering documentation. Because of the violently changing state of the art of data acquisition, storage, and retrieval the description of the plan does not embrace the details of a total decade of phased change. Rather it describes actions that can and should be taken in the relatively near future, and proposes a continuing series of later studies to keep this plan current for the full decade. -

"Manufacturing plan : Saturn V : booster stage S-IC. Volume 1."

This procedure provides the necessary information for the fabrication and assembly of the Saturn C-5 booster stage S-IC. The manufacturing methods outlined herein represent techniques that will be utilized both at Michoud and MSFC wherever possible. The concepts and methods outlined are of a preliminary nature consistent with the stage of design at this time. These concepts and methods are subject to change. This Manufacturing Plan will be periodically updated to reflect such changes. The processes and techniques proposed in this Manufacturing Plan are generally within the present state of the art, consistent with reliability requirements for manned space flight and advocated for use with the limited manufacturing facilities of the Marshall Space Flight Center and the Michoud Production Facility.; Includes memorandum dated 15 Jan. 1963 from J. H. Chesteen, Chief, Engineering Planning Section. M-ME-SE.; Includes memorandum from J. H. Chesteen and N. E. Johansen to W. B. Edmiston and W. R. Kuers--subject: Integration Boeing-MSFC Manufacturing plan. December 18, 1962. -

"Manufacturing plan : Saturn V : booster stage S-IC. Volume 2."

Manufacturing plan for Saturn V Booster stage S-IC -

"Manufacturing plan for Saturn S-II, Stages 16-25."

Manufacturing plan for for SII stages 16 through 25. -

"Manned space flight schedules. Vol. III, launch vehicles : book 3, Saturn V."

OMSF Program Status Review October 1965.; Edition "A". -

"Manned space flight schedules. Vol. III, launch vehicles : book 2, Saturn IB."

OMSF program status review October 1965.; Edition "A". -

"Propulsion and Vehicle Engineering Laboratory monthly progress report (April 1, 1967, through April 30, 1967)."

Monthly progress report between the month of April. -

"Michoud and Mississippi test operations : May 1965."

This document contains copies of management charts and photographs maintained in the Management Information Office of the Executive Staff on Michoud and Mississippi Test Operations. Information on other MSFC activities and facilities will be published in separate volumes as indicated on the following page. Most of these charges are included in Dr. von Braun's, Dr. Rees' and Mr. Gorman's Management Information Consoles. -

"Meticulous engineering."

The need for high reliability and great care in modern engineering is stressed. Disciplines to eliminate or decrease errors are described. College courses should interweave this approach into study projects. -

"Methods for cleaning electronic components and subassemblies."

In describing the cleaning of electronic components and subassemblies, it must be taken into consideration that each part to be cleaned presents an individual problem. The method of cleaning must be tailored to the type of part to be cleaned as well as to the type of soil to be removed. This paper reviews some of the methods used in cleaning electronic arts, particularly printed circuits, as well as other critical hardware which is used in support of electronic assemblies. Some of the methods covered include the use of abrasives, acids, solvents and alkalies, and the employment of these in combination with ultrasonic and other automatic systems. The clean room in use at IBM Huntsville is described briefly, along with the solutions and solvents used in cleaning electronic and supporting parts. Cleanliness- requirements for the area and the materials, together with procedures for meeting them give added emphasis to the critical nature of today's contamination control programs. The paper concludes with a summary of the cleaning procedures and the cleanroom benefits to be obtained by using present day technologies to improve them. -

"NASA management programs."

Address by Dr. George E. Mueller, Associate Administrator for Manned Space Flight, National Aeronautics and Space Administration; Joint AIAA/CASI Meeting, Montreal, Canada, July 8, 1968. AS DELIVERED.; Includes charts. -

"NASA management programs."

Address by Dr. George E. Mueller, Associate Administrator for Manned Space Flight, National Aeronautics and Space Administration before the Ninth National Conference of United Press International Editors and Publishers, October 8, 1968. -

"H-1 rocket engine: models H-1C and H-1D : technical manual engine data."

Poor jpeg of a screenshot of a word-document.