Browse Items (1976 total)

Sort by:

-

"Contract Status Report."

Saturn funded contracts in excess of $100,000. Lists contracts by contract numbers. Gives contractor, value, place of performance and scope of work.; There is a burned stripe across one page. -

"Contractor Program Procedure".

Outlines various procedures for Saturn V contractors. -

"Contractor Program Procedures".

A collection of various procedures. Archive copy is a photocopy. There is no continuous numbering in this document. -

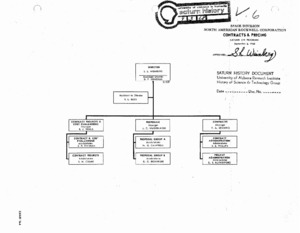

"Contracts & Pricing: Saturn S-II Program".

Indicates the various levels and responsibilities within the Saturn V pricing and contract personnel. September 3, 1968.; Approved S. L. Weinberg. -

"Contracts for Saturn Upper Stages S-IV and S-V".

Details contracts for upper stages of Saturn IV and Saturn V and includes illustrative appendixes. Archive copy is a photocopy. -

"Corrosion Problems Associated with Space Launch Vehicles".

A document reporting various space vehicle corrosion issues. Original is photocopy. -

"Corrosion problems associated with the Saturn space vehicles."

Corrosion problems associated with space vehicles, in general, are discussed as contrasted to those problems experienced with structures in an earth atmosphere. Primary emphasis is placed on structural alloys in this discussion, although some corrosion failures experienced in various mechanical components are described. General corrosion prevention measures are indicated, and solutions to specific corrosion failures described. Major failures experienced have been attributed to stress corrosion cracking, rather than general or galvanic type corrosion. Most such failures have occurred with only five different materials: three aluminum alloys - 7075-T6, 7079-T6, and 2024-T6; and two precipitation hardening stainless steels - 17-7PH and AM 355. Corrective actions were different in each case, but involved either a complete change to another material, a change to a different temper of the same alloy, or a modification of the heat treatment and/or general processing techniques. General conclusions are that the types of failures described could be avoided by: a more suitable selection of alloys in the initial design, a realistic review of the environments that could be encountered in the service lifetime of the component, lowering stresses, improving process controls, and effecting better familiarization of design personnel with the with the overall stress corrosion problem in an effort to reduce human error.; Preprint 18e.; Materials for re-entry and spacecraft systems - spacecraft materials.; Materials Conference, Philadelphia, Pennsylvania, March 31 - April 4, 1968. -

"Countdown to Liftoff".

This is an article from the Boeing Magazine. The Archive copy is a very poor photocopy and is difficult to read.; About the time the S-IC-1 booster is lifting the first Apollo/Saturn V from the launch pad on its maiden unmanned flight next year, a Boeing systems test crew will begin static testing the S-IC-4 at Devils Swamp, Mississippi (MTF). Starting with S-IC-4, all Saturn V first stage boosters will be captive fired at MTF. At present, S-IC firings are conducted by MSFC's test laboratory at Huntsville. The first flight stage, the S-IC-1, was placed in the static test stand on 24 January 1966 and completed its test program 25 Feb. It was removed from the stand March 14 and is undergoing post-firing checkout. it is due to be shipped this summer to KSC where it will be mated to the two upper stages of Saturn V, the IU and Dummy Apollo payload. The S-IC-2 went into the static stand on March 22 and is being tested during April The S-IC-3 also will be tested at Huntsville in 1966. The job of putting the world's largest and most powerful rocket together will be accomplished in the world's largest building, the 52-story vehicle assembly building. -

"Countdown trials start for launch."

News article detailing how the crew of the Apollo 8 are preparing for launch with a "dry run."