Browse Items (716 total)

Sort by:

-

"Classification review of Saturn I/IB quarterly film report, no. 24."

Memo to Lee Cropp, I-RM-D concerning security classification. -

"Columbia and eagle prepared for launch."

A news article detailing the scheduled launch for the Apollo 11. "Eagle" is the name of the lunar module and "Columbia" is the name of the service module. -

"Comments on Problems Relating to the Lunar-Landing Vehicle."

"This technical note concerns some of the problems encountered with the landing of a payload on the moon. The main problem areas such as guidance, velocity control and impact considerations are discussed. Although no final conclusions or designs are intended, it is hoped that the material presented will serve as a guide for future detailed work." -

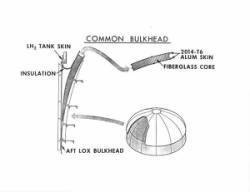

"Common bulkhead drawing."

8 x 10 inch black and white photograph; This is a cutaway drawing of the bulkhead with information about the LH2 tank skin, insulation, Aft LOX bulkhead, 2014-T6 alum skin and fiberglass core. Part of an envelope with photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

"Communication from the President of the United States transmitting the report of the President's Materials Policy Commission, June 1952."

Includes bibliographical references.; Original format: paperback book (42 pages); Cover title: Resources for freedom : the outlook of energy resources, volume III. Contains plans and analyses of potential future energy sources. -

"Communication-System Blackout During Reentry of Large Vehicles".

This paper was published in the Proceedings of the IEEE, volume 55, number 5, May 1967.; ABSTRACT: Much of the theoretical research on reentry blackout is in a format difficult for the communications design engineer to use in his system analysis. This paper derives simplified equations for the average sheath power loss that may be added (in dB) to the usual space loss to obtain an approximate total propagation loss. The plasma and sheath properties are discussed in detail but largely without supporting mathematics, in order to give the design engineer a better understanding of the overall problem. For the same reason and to provide insight into the final results, the average radiated power is found, using both intuitive and rigorous techniques. Several graphs of plasma properties are included in the development as an aid to numerical computation, and results are compared with the work of other authors. -

"Company announces scholarship winners: Space Division places 9 of 21 boys and 16 girls."

A news article detailing the winners of scholarships from a competition held by Space Division. This contest was held for the children of Space Division employees. -

"Component Failure Effect on Systems: An Analytical Model".

Prepared by R. L. Parkhill, Section Chief, Saturn S-IVB Reliability Analysis and J. Pauperas JR., Asst. Section Chief, Saturn S-IV Reliability Analysis. Presented to the 4th Annual Seminar on Reliability for Space Vehicles, Los Angeles, California, December 6, 1963. This paper presents techniques originated by Douglas Engineering working under NASA contract NAS7-1. Prepared as a record of the study conducted for the Administrative Engineer on the Department Overhead Account No. 9703.; SUMMARY: In today's complex systems, such as Saturn, many traditional reliability analysis concepts are not acceptable. Because of time and budget restrictions, and the requirement to provide a "man rated" space vehicle, the Douglas Saturn Engineering Reliability Section has developed a new analytical approach; it is called "criticality ranking". It is a "totem pole" of components whose single failure may lead to system loss. "Criticality ranking" is one of the results of an analytical model which encompasses failure effect and reliability prediction. This paper describes this analytical model, discusses some of the techniques and ground rules, and presents examples. A discussion of the application of the results is also included. -

"Computer Controlled Power Application for the Saturn Launch Vehicle".

This paper describes a real-time digital computer program that controls the application of electrical power to the S-IVB stage of the Saturn vehicle at Cape Kennedy, Florida. Douglas Aircraft Company, the S-IVB stage manufacturer, provided NASA with the program requirements relative to the energizing sequence, voltage and current measurement tolerances, and vehicle system operational tests. International Business Machines Corporation provided NASA with the computer program to satisfy the task requirements. The program conjoined the components of the Electrical Support Equipment (two RCA 110A computers and control and instrumentation devices) into a closed loop system. The supporting operating system program by IBM is described. -

"Computer Redundancy: Design, Performance, and Future".

Discusses the importance of redundancy as a safety measure in electronic systems. -

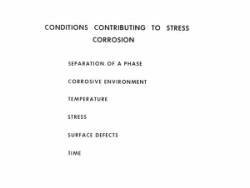

"Conditions contributing to stress corrosion [list] photograph."

8 x 10 inch black and white photograph. A photograph of a list of things contributing to stress corrosion. Referenced by "Materials in Space Exploration." Is part of envelope containing photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

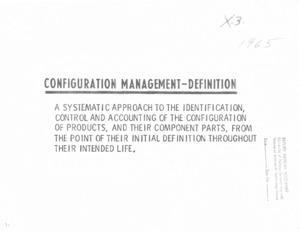

"Configuration Management-Definition".

Configuration management: Definition, requirements, organization, policy and procedure documents, contractual documents. -

"Contract Status Report."

Saturn funded contracts in excess of $100,000. Lists contracts by contract numbers. Gives contractor, value, place of performance and scope of work.; There is a burned stripe across one page. -

"Contractor Program Procedure".

Outlines various procedures for Saturn V contractors. -

"Contractor Program Procedures".

A collection of various procedures. Archive copy is a photocopy. There is no continuous numbering in this document. -

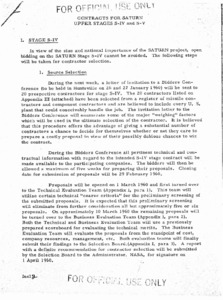

"Contracts & Pricing: Saturn S-II Program".

Indicates the various levels and responsibilities within the Saturn V pricing and contract personnel. September 3, 1968.; Approved S. L. Weinberg. -

"Contracts for Saturn Upper Stages S-IV and S-V".

Details contracts for upper stages of Saturn IV and Saturn V and includes illustrative appendixes. Archive copy is a photocopy. -

"Corrosion Problems Associated with Space Launch Vehicles".

A document reporting various space vehicle corrosion issues. Original is photocopy. -

"Corrosion problems associated with the Saturn space vehicles."

Corrosion problems associated with space vehicles, in general, are discussed as contrasted to those problems experienced with structures in an earth atmosphere. Primary emphasis is placed on structural alloys in this discussion, although some corrosion failures experienced in various mechanical components are described. General corrosion prevention measures are indicated, and solutions to specific corrosion failures described. Major failures experienced have been attributed to stress corrosion cracking, rather than general or galvanic type corrosion. Most such failures have occurred with only five different materials: three aluminum alloys - 7075-T6, 7079-T6, and 2024-T6; and two precipitation hardening stainless steels - 17-7PH and AM 355. Corrective actions were different in each case, but involved either a complete change to another material, a change to a different temper of the same alloy, or a modification of the heat treatment and/or general processing techniques. General conclusions are that the types of failures described could be avoided by: a more suitable selection of alloys in the initial design, a realistic review of the environments that could be encountered in the service lifetime of the component, lowering stresses, improving process controls, and effecting better familiarization of design personnel with the with the overall stress corrosion problem in an effort to reduce human error.; Preprint 18e.; Materials for re-entry and spacecraft systems - spacecraft materials.; Materials Conference, Philadelphia, Pennsylvania, March 31 - April 4, 1968. -

"Countdown to Liftoff".

This is an article from the Boeing Magazine. The Archive copy is a very poor photocopy and is difficult to read.; About the time the S-IC-1 booster is lifting the first Apollo/Saturn V from the launch pad on its maiden unmanned flight next year, a Boeing systems test crew will begin static testing the S-IC-4 at Devils Swamp, Mississippi (MTF). Starting with S-IC-4, all Saturn V first stage boosters will be captive fired at MTF. At present, S-IC firings are conducted by MSFC's test laboratory at Huntsville. The first flight stage, the S-IC-1, was placed in the static test stand on 24 January 1966 and completed its test program 25 Feb. It was removed from the stand March 14 and is undergoing post-firing checkout. it is due to be shipped this summer to KSC where it will be mated to the two upper stages of Saturn V, the IU and Dummy Apollo payload. The S-IC-2 went into the static stand on March 22 and is being tested during April The S-IC-3 also will be tested at Huntsville in 1966. The job of putting the world's largest and most powerful rocket together will be accomplished in the world's largest building, the 52-story vehicle assembly building. -

"Countdown trials start for launch."

News article detailing how the crew of the Apollo 8 are preparing for launch with a "dry run." -

"Craft destined for use in lunar landing mission."

News article detailing how the Apollo spacecraft 107 command modules are planned to be used in future space-missions. -

"Crew Briefing : Instrument Unit Stage Presentation".

Document outlining different slides of a presentation containing numerous organizational charts, diagrams and bullet-list points. -

"Crew Briefing : Instrument Unit Stage Presentation".

Document outlining different slides of a presentation containing numerous organizational charts, diagrams and bullet-list points. -

"D5-13197 manufacturing plan: AAP."

This Manufacturing plan is prepared in response to the Apollo Applications Program request for proposal No. 1.1.; PURPOSE: The purpose of this document is to present a Boeing plan for the manufacturing effort required to provide hardware and support for the installation and checkout of Experiment Packages and related equipment in the Apollo Systems Modules. -

"Data Sheet J-2 Rocket Engine."

A datasheet describing the function of the J-2 rocket engine. -

"Data Sheet: H-1 Rocket Engine."

News from Rocketdyne. -

"Dec. 21 - 4:51 a.m. -One of great explorations of all time begins."

News article detailing how Apollo 8 is ready for launch and the anticipation surrounding it. -

"Decision Procedure for Minimizing Costs of Calibrating Liquid Rocket Engines."

Prior to acceptance of a liquid rocket engine for use in Saturn vehicles, the average thrust of two consecutive tests without an intervening calibration must satisfy specification requirements. The contractor may recalibrate after the first and subsequent tests if he so chooses, based upon decision limits, until the above requirement is met. -

"Design and Development of a 1,500,000-Pound-Thrust Space Booster Engine."

Describes the F-1 engine design and components. -

"Design and Development of a Zero-G Vapor Liquid Separator For Use in Cryogenic Fluid Power Systems."

During long coast periods of zero-gravity, storage vessels for the cryogenic liquids proposed for use in some power transmission systems undergo random distribution of the liquid and vapor phases therein. Thus, when heat flow into the vessel causes the vessel pressure to build-up requiring venting to maintain a safe value, the likelihood of venting the valuable liquid phase, as well as the vapor, results. To preclude this eventuality, various devices for separating the liquid and vapor phases and venting just the vapor have been studied and carried into the experimentation stages. -

"Design and Use of Fault Simulation for Saturn Computer Design."

Describes different aspect of the Fault Simulation for Saturn computer design. -

"Design Concepts of Ground DDAS in Saturn 1B/V ESE."

In the Saturn IB/V programs the sheer quantity of data required for computer processing and ESE display makes it necessary to provide an efficient data acquisition system. For much of the data originating in the launcher this requirement is satisfied by the Ground Digital Data Acquisition System (DDAS). This paper provides a technical description of the Ground DDAS with emphasis placed on the unique design concepts of this telemetry system. -

"Design of the Saturn S-IV Stage Propellant Utilization System."

Describes the SIV vehicle and its components. Presented at: IRE International Convention. -

"Design, Development, and Fabrication of a Prototype Hydraulic Transformer."

For presentation to the Society of Automotive Engineers, 16 September 1964, Boston, Massachusetts. ABSTRACT: This paper discusses the design, development and fabrication of a prototype hydraulic transformer, Hydro-Aire Model No. 05-055, performed in fulfillment of the requirements of Contract No. NAS 8-5264 for NASA Marshall Space Flight Center. The Hydraulic Transformer described is designed to pump hydraulic oil at a flow of 100 GPM with a pressure rise of 4000 psi, and does this work by utilizing as a power source the flow of RP-1 rocket fuel at a pressure of 1900 psig. The Hydraulic Transformer built to handle this combination of flows and pressures, unprecedented in such devices, has a weight of only 70 pounds for the first development model. The development of this unit is discussed and future development improvements are mentioned. -

"Development and Utilization of Computer and Test Programs for Checkout of Space Vehicles."

A computer system was designed to allow test engineers to progressively employ automation in the checkout of the Uprated Saturn I and Saturn V space vehicle programs and still allow manual control of the checkout process. A two-computer system was selected by National Aeronautics and Space Administration, and the International Business Machines Corporation was chosen to provide the programming engineering necessary to implement these objectives. Space vehicle checkout, prior to launch, may be characterized by controlling, monitoring, and testing the vehicle and its subsystems through the use of ground support equipment (GSE).; IBM Huntsville Library.; Presented at AIAA Conference, XVIIth International Astronautical Congress, Madrid, Spain, October 10-15, 1966 by Edward A. Robin, Manager, Vehicle Test Programming Department. -

"Development Effort to Achieve Reliability."

Presented at the 6th West Coast Reliability Symposium, University of California at Los Angeles, Los Angeles, California, 20 February 1965.The development of a large liquid rocket engine can represent the expenditure of several hundred million dollars of effort. Before 30 percent of the contracted development funds have been expended, however, the engine will probably have operated for the mission duration. The capability to operate at least one successful test early in a development program is evidence of achieving a minimal reliability level, but the major objective of the development program is producing a design which performs reliably. A rocket engine reliability prediction must view reliability as a dynamic concept, constantly being altered by development effort. -

"Development of LOX-Hydrogen Engines for the Saturn Apollo Launch Vehicles."

During the development of the RL-10 and J-2 engines, many problems were encountered. Solutions to the significant problems are contained. A description of these LOX-Hydrogen engines, outlining the unique features of each will be given. Performance parameters for both engine systems are tabulated. Specific applications to various stages are shown. -

"Development of LOX/RP-1 Engines for Saturn/Apollo Launch Vehicles."

The development of liquid rocket engines follow similar patterns regardless of engine size. During the development of the H-1 and F-1 engines, many problems were encountered. Methods of solving the combustion instability problem are discussed. A description is given of the major components of each engine, outlining their unique features. The requirements for an insulation cocoon are discussed. Problems associated with materials substitution are provided; also highlighted is the fact that problems occur after engine deliveries and require continued development support. Safety features incorporated on the engines are mentioned. Solution to problems encountered in flight are discussed. Upratings of both engines systems are presented graphically.; On the NASA Technical Reports Server (NTRS) unclassified. Can also be found on AIAA. -

"Development of Separable Connectors for the Saturn S-IV Stage."

The purpose of this paper is to present information, in the area of separable connectors as they pertain to the Saturn S-IV Program.