Browse Items (12 total)

Sort by:

-

"1965 Publications," Materials Division, George C. Marshall Space Flight Center.

This document is a compilation of abstracts of NASA Technical Memorandums and MSFC Internal Notes, written by personnel of the Materials Division and released during 1965. -

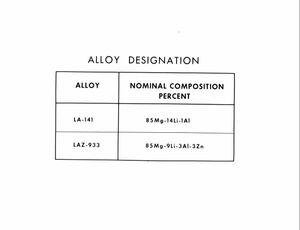

"Alloy designation" Table.

8 x 10 inch black and white photograph that displays a table of two elements and their molecular makeup. Table includes the alloy of LA-141 and LAZ-933. -

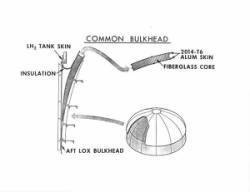

"Common bulkhead drawing."

8 x 10 inch black and white photograph; This is a cutaway drawing of the bulkhead with information about the LH2 tank skin, insulation, Aft LOX bulkhead, 2014-T6 alum skin and fiberglass core. Part of an envelope with photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

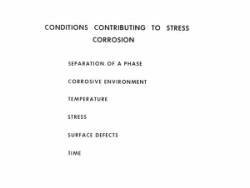

"Conditions contributing to stress corrosion [list] photograph."

8 x 10 inch black and white photograph. A photograph of a list of things contributing to stress corrosion. Referenced by "Materials in Space Exploration." Is part of envelope containing photos accompanying C. E. Cataldo paper "Materials in Space Exploration." -

"Corrosion Problems Associated with Space Launch Vehicles".

A document reporting various space vehicle corrosion issues. Original is photocopy. -

"Corrosion problems associated with the Saturn space vehicles."

Corrosion problems associated with space vehicles, in general, are discussed as contrasted to those problems experienced with structures in an earth atmosphere. Primary emphasis is placed on structural alloys in this discussion, although some corrosion failures experienced in various mechanical components are described. General corrosion prevention measures are indicated, and solutions to specific corrosion failures described. Major failures experienced have been attributed to stress corrosion cracking, rather than general or galvanic type corrosion. Most such failures have occurred with only five different materials: three aluminum alloys - 7075-T6, 7079-T6, and 2024-T6; and two precipitation hardening stainless steels - 17-7PH and AM 355. Corrective actions were different in each case, but involved either a complete change to another material, a change to a different temper of the same alloy, or a modification of the heat treatment and/or general processing techniques. General conclusions are that the types of failures described could be avoided by: a more suitable selection of alloys in the initial design, a realistic review of the environments that could be encountered in the service lifetime of the component, lowering stresses, improving process controls, and effecting better familiarization of design personnel with the with the overall stress corrosion problem in an effort to reduce human error.; Preprint 18e.; Materials for re-entry and spacecraft systems - spacecraft materials.; Materials Conference, Philadelphia, Pennsylvania, March 31 - April 4, 1968. -

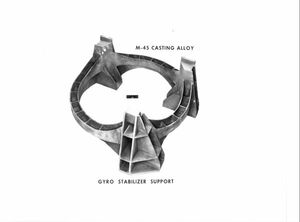

"M-45 casting alloy : Gyro stabilizer support."

8 x 10 inch black and white photograph of a gyro stabilizing support. -

"Materials in space exploration."

This paper presents a general review of major structural alloys that have been used in liquid rockets and space vehicles, the current state-of-the-art as applied to the Apollo launch vehicle systems, and discusses some materials currently under development for future requirements in vehicles for space exploration. Some aspects of the importance of corrosion resistant materials and suitable protective measures are discussed, as applied to both flight hardware and associated ground support equipment. -

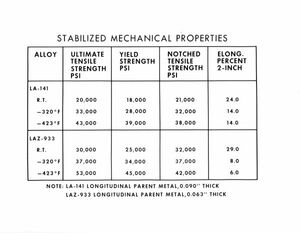

"Stabilized mechanical properties [table] photograph.

8 x 10 inch black and white photograph including a table that displays the stabilized mechanical properties of the following alloys: :LA-141 and LAX-933. -

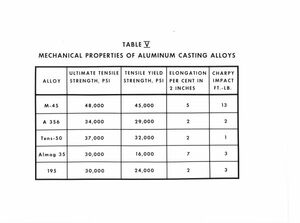

"Table V : mechanical properties of aluminum casting alloys."

8 x 10 inch black and white photograph of a table detailing the tensile strength, tensile yeild, elongation per cent and charpy impact of alloys. -

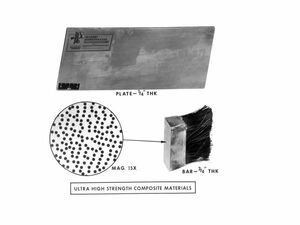

"Ultra high strength composite materials."

8 x 10 inch black and white photograph which displays an image that includes the plate, bar and the magnification of the bar to display its molecules. -

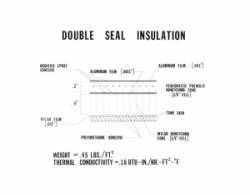

Double seal insulation [drawing] photograph.

8 x 10 inch black and white photograph.; Drawing contains information about the modified epoxy adhesive, aluminum film, mylar film, perforated phenolic honeycomb core, tank skin, mylar honeycomb core, polyurethane adhesive, weight and thermal conductivity.; Photo negative no. 651746 M-268.