Browse Items (5 total)

Sort by:

-

"Alignment Tool Aids in Large Tank Fabrication."

Includes the clipping "Clamping Tool Aligns Odd-Shaped Sections for Welding" from <i>Design News</i>, September 4, 1963, written by Margaret A. Maas. -

Theoretical liquid propellant performance calculations

Archive copy is a photocopy.; The purpose of these writings is to compile in one volume the basic elements of thermodynamics and gas dynamics which are useful in the evaluation of thrust chamber performance. It is presumed that the reader will have had an elementary course in thermodynamics and gas dynamics. The discussion of topics useful in evaluating thrust chamber performance is, of necessity, limited to these physical effects amenable to other areas that are as yet in the research stage of development. The author would like to take this opportunity to express his gratitude to Mr. G. S. Gill for many stimulating discussions on this subject. Thanks are due to Mr. D. J. Kuyper for permission to utilize his discussion on elastic-plastic strain and its application to nozzle throat area change. Finally, the author wishes to express his gratitude to his wife, Alice, who typed the bulk of the manuscript. -

"The production of large tanks for cryogenic fuels"

Archive copy is a poor photocopy. Prepared for presentation at Deutsche Gesellschaft fur Raketentechnik und Raumfahrt. (German Society for Rocket Technology and Astronautics). Given by E. Harpoothian, Chief Engineer, Structures Department, Development Engineering.; Tanks for cryogenic fluids, as used in the Saturn space vehicles, have reached an advanced stage of design and development. Many of the structural features of the NASA/Douglas Saturn tanks, fabricated of 2014-T6 aluminum alloy, were first developed for the booster of the Thor ballistic missile, which later found extensive use in putting space vehicles into orbit. There is a mutual dependence of important factors related to design concepts, selection of materials, processing techniques, and fabrication methods. It is shown that this mutual dependence must be considered if a successful vehicle is to emerge from design and development. Details of vehicle structure, provision for insulation, and manufacturing methods are presented. Criteria for the selection of materials is shown to be dependent on strength, ductility, weldability, toughness, fabricability, behavior at cryogenic temperatures, and on manufacturing methods and inspection techniques. -

"The development of a bonded common bulkhead for Saturn."

A Part of the development of the Saturn S-IV/S-IVB stage the Douglas Aircraft Company has pioneered in the development of the cryogenic common bulkhead. The term common bulkhead is derived from the design function of the bulkhead, which is to separate the two cryogenics, liquid hydrogen and liquid oxygen, in a single tank, thereby shortening the stage and eliminating the necessity for two separate bulkheads and the associated interstage structure. The common bulkhead is structurally adequate to withstand both the thermal and the pressure loads from both the hydrogen and the oxygen tanks, and it has sufficient insulation properties to prevent the liquid hydrogen from freezing the liquid oxygen. Another benefit from the common bulkhead is that it permits a reduction in the total length of the vehicle, thereby reducing the bending moments. -

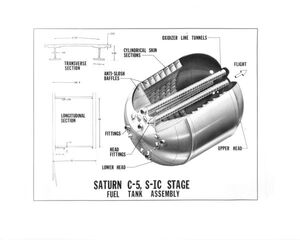

"Saturn C-5, S-IC, stage fuel tank assembly."

8 x 10 inch black and white diagram of a Saturn fuel-tank assembly cross-section.