Browse Items (20 total)

Sort by:

-

"Apollo Vehicle Propulsion Systems."

This paper discusses the propulsion requirements for various stages of the Apollo vehicles and the development of these engines. -

"Recent NASA experience with hydrogen engines."

This paper presents a review of the experience which has accumulated in the development of the Liquid Hydrogen J-2 and RL10 rocket engines. These engines are being developed by the Rocketdyne Division of North American Aviation and Pratt & Whitney Aircraft, a Division of United Aircraft Corporation respectively.; On NASA Technical Reports Server (NTRS) as Unclassified; No Copyright; Unlimited; Publicly available. Also found on AIAA site. -

"Recent NASA experience with hydrogen engines."

This paper presents a review of the experience which has accumulated in the development of the Liquid Hydrogen J-2 and RL10 rocket engines. These engines are being developed by the Rocketdyne Division of North American Aviation and Pratt & Whitney Aircraft, a Division of United Aircraft Corporation respectively.; On NASA Technical Reports Server (NTRS) as Unclassified; No Copyright; Unlimited; Publicly available. Also found on AIAA site. -

"The Challenge of Change vs the Control of the Process."

The introduction states, "This paper is designed to present the Rocketdyne engine program as it applies to the Saturn launch vehicles and will apply to the Apollo program of manned flight to the moon (Fig. 1). The vehicle that will launch this flight is the Saturn V, the largest and most powerful of the Saturn family. This vehicle, 362 feet tall and 33 feet in diameter, will be capable of sending a 45-ton payload to the moon or placing a 120-ton payload in earth orbit. Five F-1 engines power the first stage of the Saturn V; five J-2 engines, the second stage; and one J-2 engine, the third stage. The thrust of the first-stage engines alone will be equivalent to 160 million horsepower. Both of these engines, the F-1 and the J-2, were designed at, and are currently being produced by Rocketdyne." -

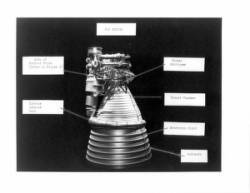

F-1 engine photograph.

8 x 10 inch black and white photograph. Engine parts are labeled. -

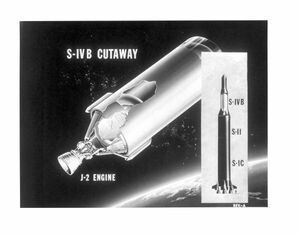

S-IVB cutaway and J-2 engine."

8 x 10 inch black and white diagram of the JII engine and the Saturn IV. -

"Saturn I : the first generation of heavy launch vehicles designed for peaceful exploration of space."

A basic description of the Saturn rockets alongside diagrams for context. -

"Nondestructive testing of space vehicle liquid propellant rocket engines."

Presented at the Western Metals Congress, Los Angeles, California, 15 March 1967.; Archive copy is a photocopy.; ABSTRACT: This report describes the various nondestructive test methods employed to evaluate materials and processes used in the manufacture of large liquid propellant rocket engines at the Rocketdyne Division of North American Aviation, Inc. The contents of the paper were purposely oriented for an audience of aerospace, design and materials engineers. A brief description of liquid propellant rocket engine reliability is presented. The relationship of standards and specifications to nondestructive testing is discussed and various test methods are described along with a discussion of their applications and limitations. The sequence of events leading up to the use of nondestructive testing in production inspection is presented. Finally, the organization of labor directly related to nondestructive testing is given. -

"Memorandum to Dr. Seamans from Mr. Holmes. Subject: F-1 engine combustion instability problems."

Memorandum discussing a presentation regarding problems that needed solving, a "Dr. Evvard's" lack of cooperation and letters to Wernher von Braun. -

"Decision Procedure for Minimizing Costs of Calibrating Liquid Rocket Engines."

Prior to acceptance of a liquid rocket engine for use in Saturn vehicles, the average thrust of two consecutive tests without an intervening calibration must satisfy specification requirements. The contractor may recalibrate after the first and subsequent tests if he so chooses, based upon decision limits, until the above requirement is met. -

"Propulsion development problems associated with large liquid rockets."

NASA technical memorandum, Propulsion and Mechanism Branch. Propulsion and Vehicle Engineering Division, Research and Development Operations. -

"Propulsion lecture."

Lecture discussing the types of propellant used in space rockets. -

"Pratt & Whitney Aircraft RL10 liquid hydrogen rocket engine"

Photograph of a Pratt & Whitney rocket engine. -

"News from Rocketdyne : Project Saturn."

Press release exploring the rockets and projects of the Saturn project. -

"A Review of Cryogenic Technology Aspects of Space Flight."

This paper was presented at the International Cryogenic Engineering Conference in Kyoto, Japan. It details the use of cryogenic technology in rocketry and how its usage created "many new techniques and deeply stimulated many fields of cryogenic technology." -

"Pratt & Whitney Aircraft RL10 liquid hydrogen rocket engine."

Photograph of a liquid hydrogen rocket engine. -

Artist's Conception of the RL10-powered Saturn S-IV Stage.

This artist's rendering of the RL10-powered Saturn S-IV stage is depicted as heading toward deep space after separation from the booster. The drawing is accompanied with a brief description of the Saturn S-IV. -

"Reliability assessment of liquid rocket engines."

Proposed for the 10th National Symposium on Reliability & Quality Control. This paper will deal with various techniques of treatment of such data and associated graphic displays. -

"Manned space flight schedules. Vol. III, launch vehicles : book 4, engines."

OMSF Program Status Review October 1965.; Edition "A" -

"Rocket engine turbo pumps for space travel."

Finding the turbopump arrangement which is best suited for a given rocket engine - space travel applications - constitutes an important task. The arrangement depends upon a large variety of different factors, such as, the engine cycle, weight, the liquids to be pumped, the cavitation performance, the bearings and their lubrication, the seals and the turbine. In this report these factors and their influence on the turbopump configuration are discussed. It is shown that three of them: weight, propellants to be pumped and obtainable suction performance have the largest influence on the selection of the turbopump. A systematic approach is outlines for the design process, which allows to arrive at a turbopump arrangement best suited for a given application.