Browse Items (716 total)

Sort by:

-

"Test Laboratory progress report" May and June.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between Feburary and March -

"Test Laboratory progress report" March and April.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between March and April. -

"Test Laboratory progress report" Febuary and March.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between Feburary and March -

"Test Laboratory monthly progress report" September.

Laboratory monthly progress report for the Saturn 1B program between dates September 1st through September 31st, 1967. -

"Test Laboratory monthly progress report" October.

Laboratory monthly progress report for the Saturn 1B program between dates October 1st through October 31st, 1967. Page 17 missing. -

"Test Laboratory monthly progress report" June.

Laboratory monthly progress report for the Saturn 1B program between dates June 1st through June 31st, 1967. -

"Test Laboratory monthly progress report" July.

Laboratory monthly progress report for the Saturn 1B program between dates July 1st through July 31st, 1967. -

"Test Laboratory monthly progress report" January.

Laboratory monthly progress report for the Saturn 1B program between dates January 1st through January 31st, 1968. -

"Test Laboratory monthly progress report" Febuary.

Laboratory monthly progress report for the Saturn 1B program between dates Febuary 1st through Febuary 31st, 1967. -

"Test Laboratory monthly progress report" December.

Laboratory monthly progress report for the Saturn 1B program between dates December 1st through December 31st, 1967. -

"Test Laboratory monthly progress report" August.

Laboratory monthly progress report for the Saturn 1B program between dates August 1st through August 31st, 1967. -

"Test Laboratory monthly progress report" April.

Laboratory monthly progress report for the Saturn 1B program between dates April 1st through April 31st, 1967. Last page of document is missing. -

"Test Laboratory monthly progress report : March, 1967."

Monthly progress report for March, 1967. -

"Telemetry system for Saturn S-I stage development."

The telemetry system used on the Saturn S-I stage for the transmission of vehicle test data is described. Multiplex and modulationtechniques such as PAM/FM/FM, SS/FM and PGM are used in the system. The diverse data requirements for developing the eight-engineliquid-fueled stage necessitated the use of a combination of severalmodulation techniques to efficiently handle the data. A cursory comparisonis made of the merits of each technique. Physical and electricalrequirements and characteristics of the system are outlined. -

"Telemetry system design for Saturn vehicles."

This paper discusses the data system requirements for large space vehicles and describes a flexible telemetry system design which is used on all stages of the Saturn IB and Saturn V vehicles. The basic vehicle telemetry design provides standard assembly building blocks forming a versatile catalogue of parts from which a stage telemetry subsystem may be assembled to meet almost any conceivable monitoring requirement. In addition to its inflight monitoring function, the telemetry subsystem also provides real time data acquisition for automatic vehicle checkout. -

"Telegraphic message : inspection requirements for S-II-1 and S-II-2 at KSC."

Photocopy of an inspection list requirements for S-II-1 and S-II-2. -

"Technological problems of the Saturn class vehicle."

Aerospace Workshop. University of Hawaii.; Includes references to slides. -

"Techniques of implementing launch automation programs" (Saturn IB space vehicle system).

This paper identifies the methods and equipment through which automation is becoming a major factor in testing and launching Saturn IB space vehicles. The merits of a digital guidance computer and its impact in extending automated checkout are stressed; also a logical basis is established for computer and manual test control. Hardware and software elements of the automated system are described, and details pertaining to reliability are emphasized. A concluding appraisal suggests that automation will play an expanding role in future test and launch operations. -

"Technique for reliability circuit design review in space electronics."

Design review is becoming a basic requirement during the design and development of military systems. The main purpose of the design review is to increase the system's inherent and operational reliability. The major portion of this paper is the result of reliability's effort to comply with Paragraph 3.6 of NPC 250-1 Reliability Program Provisions for Space Contractors. The design review to be discussed is a reliability circuit design review with emphasis placed on what should be reviewed and the review techniques employed. The basic circuit design review prerequisites, component parts and their ratings, are discussed at the beginning of this paper. The remainder deals with the organization and reviewing of circuits. The review items include worst-case circuit performance, component applications, failure mode analysis, noise rejection, electrical stress, and the determination of component temperatures. Many examples are included to illustrate how each item was accomplished. This paper is intended not only to give the reliability analyst cognizance of basic design problems and troublesome circuits, but also, to aid him in formulating a design review program. -

"Technician inspects an RL10 liquid hydrogen engine."

A technician inspects an RLlO liquid hydrogen rocket engine OD the assembly floor. of Pratt & Whitney Aircraft's Florida Research and Development Center. The 115,000-pound-thrust RLlO was designed and developed for the National Aeronautics and Space Administration's Saturn S-IV azld Centaur space vehicles. -

"Technical survey of ABMA activities."

Handwritten notes on the document.; Archive copy is a poor photocopy. -

"Technical problems in on-board checkout systems."

For the purposes of this paper, an onboard checkout system is defined as a system which is built into prime flight equipment, flies with it, and permits a checkout capability to exist during all the major phases of the test and mission life of that prime equipment. Varying degrees of capability may exist in such a system, depending on what is designed into it. This, in turn, is generally dependant on life and mission requirements of the prime equipment, degree of mission checkout required, reliability restrictions,redundancy levels, data management scheme, and equally important, state of the art . Not all checkout can be accomplished with onboard equipment. Mechanical system problems such as leak detection, for example, require techniques that cannot be remotely controlled and evaluated today. On the other hand, such things as in-flight telemetry have been used for quite a long time and will continue to be used for onboard checkout. -

"Technical information summary concerning Saturn vehicle SA-3."

This memorandum outlines, through a series of sketches, some of the important features and sequences concerning the third SATURN flight vehicle. The sketches are devoted primarily to the control and instrumentation aspects of the vehicle but also touch on the launch facility and countdown schedule. -

"Technical information summary concerning Saturn vehicle SA-3."

This memorandum outlines, through a series of sketches, some of the important features and sequences concerning the third SATURN flight vehicle. The sketches are devoted primarily to the control and instrumentation aspects of the vehicle but also touch on the launch facility and countdown schedule. -

"Technical Information Summary Apollo-9 (AS-504) Apollo Saturn V Space Vehicle."

The document presents a brief and concise description of the Apollo 9 Saturn Space Vehicle. -

"Technical information summary Apollo-10 (AS-505) Apollo Saturn V space vehicle."

The document presents a brief and concise description of the AS-505 Apollo Saturn Space Vehicle. Where necessary, for clarification, additional related information has been included. -

"Technical Information Summary Apollo 8 (AS-503) Apollo Saturn V Space Vehicle."

This document is prepared jointly by the Marshall Space Flight Center laboratories R-AERO-P, R-ASTR -S, and R-P&VE-VN . The document presents a brief and concise description of the AS-503 Apollo Saturn Space Vehicle. Where necessary, for clarification, additional related information has been included. It is not the intent of this document to completely define the Space Vehicle or its systems and subsystems in detail. The information presented herein, by text and sketches, describes launch preparation activities, launch facilities, and the space vehicle. This information permits the reader to follow the space vehicle sequence of events beginning a few hours prior to liftoff to its journey into space. -

"Technical History of Saturn."

Draft of working paper. Typed with handwritten notes (title and author) and pages. Copy in MSFC files noted on first page. -

"Technical facilities & equipment digest."

This document portrays the capability of technical facilities and equipment at the George C, Marshall Space Flight Center (MSFC) , one of three basic field centers under the NASA Office of Manned Space Flight. -

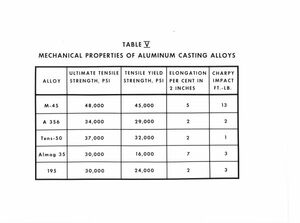

"Table V : mechanical properties of aluminum casting alloys."

8 x 10 inch black and white photograph of a table detailing the tensile strength, tensile yeild, elongation per cent and charpy impact of alloys. -

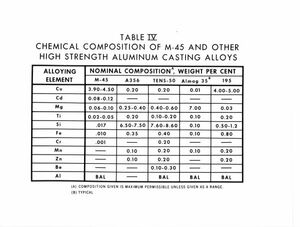

"Table IV : chemical composition of M-45 and other high strength aluminum casting alloys."

8 x 10 inch black and white photograph of a graph displaying different alloys and comparing their 'nominal composition weight per cent' to one another. -

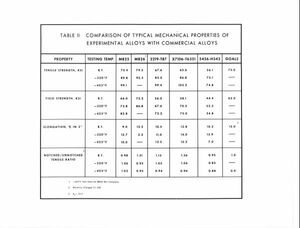

"Table II : comparison of typical mechanical properties of experimental alloys with commercial alloys."

8 x 10 inch black and white photograph of a table comparing the tensile strength of each alloy in relation to a desired goal. -

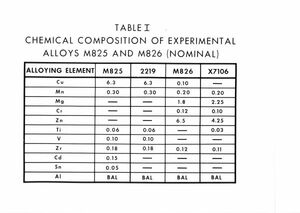

"Table I : chemical composition of experimental alloys."

8 x 10 inch black and white photograph of a table reperesenting the chemical composition of alloys M825 and M826. -

"Systems applications in orbital launch operations."

The objective is to examine the technical requirements and feasibility of conducting orbital launch operations with systems now in the development phase. In order to maintain realistic constraints on the analysis, the Saturn S-IVB stage has been used as an example of present stage technology. The requirements, procedures and complexity of operations for orbital assembly and launch are discussed. The primary design requirement for orbital assembly and launch operations is increased orbital stay time (from hours to days or weeks). -

"System safety handbook."

The testing of a hardware system consists of' subjecting it to carefully controlled operating conditions for the purpose of demonstrating that this system performs its function properly. -

"System engineering propulsion, III-C-1."

Page numbering is inconsistent; there are no pages numbered 14 - 17. Some pages have handwritten numbers, others have no numbers at all.; The print quality of many pages is poor. Discusses the definition and function of propulsion as well as how to most effectively employ it . -

"System description for Saturn vehicle (SA-1 through SA-4)."

Missing pages iv, 3, 6 to 8. Photocopy of files containing sections of the project. -

"Survey of Saturn stage test and checkout computer program development."

This survey of the Saturn Stage Test and Checkout Computer Program Development contains a summary description of the systems developed for factory and static test of the stages of the SATURN IB and SATURN V Vehicles. The responsibilities of the MSFC and stage contractor organizations that are involved in test and checkout computer program development are briefly described. The test and checkout hardware and software (computer program) systems are given for each stage and for each site where tests are conducted. The systems and procedures that are used for program production verification, documentation, and change control required for the implementation of planned computer programs are included. Notes are included in the report to indicate what material is missing or incomplete. No attempt has been made to draw any conclusions regarding the automatic test and checkout systems being developed for each stage and the manner in which the efforts are organized, scheduled, and implemented. This document has been based on material provided by stage contractors and by components of MSFC through May 1, 1966. COMPUTER SYSTEMS SECTION. VEHICLE SYSTEMS INTEGRATION BRANCH. VEHICLE SYSTEMS CHECKOUT DIVISION.; SR-QUAL-66-3. -

"Structure of the NASA/Grumman lunar module."

Describes the structure and function of each part of the NASA Lunar Module -

"Structural problems of large space boosters."

Report discussing the flaws in having large rocket boosters.