Browse Items (716 total)

Sort by:

-

"Tooling for aerospace application."

Presented to the American Ordnance Association. A presentation on Saturn S-IC Tooling in order to demonstrate the trend towards larger tooling support. Focuses on the tank-structures primarily. -

"Tool and Engineering Branch publication report."

Report list detailing the state of manufacturing plans as either "Rough" or "Final" drafts. -

"Toftoy statement to Senate Investigation Committee": Development of the Nike system.

Narrative report of general H.N. Toftoy - Informal interview with Mr. Robert E. Dunne, Assistant Counsel of the Senate Permanent Investigating Subcommittee, in the presence of Mr. P. K. Schaeppi. -

"Timing and countdown systems handbook."

The purposes of this handbook are to present the John F. Kennedy Space Center (KSC) Timing and Countdown Systems Operations Plan, to provide a description of the systems in use, to familiarize personnel engaged in space vehicle checkout and launch operations with available KSC timing and countdown services and to show how these services may be obtained. -

"Thermal models of Jupiter and Saturn"

One of the orange Aid Preprint Series in Nuclear Astrophysics by W. B. Hubbard, California Institute of Technology, Pasadena, California.; Argues that the Saturnian models are flawed as their predictions do not line up with detected gravitational events. -

"The use of wind shears in the design of aerospace vehicles."

Prepared for presentation at the 23rd Meeting of the Structures and Materials Panel, AGARD, October 4-11,1966, ONERA, Paris, France.; ABSTRACT: The relative influence of various wind profile properties and disturbances on launch vehicle flight dynamic response is studied. Particular emphasis is placed on the influence of wind shears and turbulence on dynamic response during the boost phase of the flight. Four hundred and seven individual detailed (Jimsphere) wind profiles are the primary wind inputs for this analysis. Time response of the vehicle to each profile is computed and a statistical evaluation of the results made. Results are obtained for the Saturn V space vehicle and conclusions drawn as to the relative influence of wind shears and turbulence vs the degree of refinement of the dynamic model of the space vehicle. -

"The uprated Saturn I - its growth potential & future role in space."

Remarks by Vaino J. Vehko, Director of Engineering, Chrysler Corporation Space Division at 30th Annual Meeting, Aviation/Space Writers Association, Las Vegas, Nevada -

"The U.S. manned space flight program: Mercury, Gemini, Apollo."

Exerpt from George E. Mueller giving a statement to Congress. -

"The TV system for the Apollo telescope mount."

Focuses on the construction and future use of the Apollo space telescope. The components described in this paper except for those listed otherwise were designed by the Space Support Division of Sperry Rand Corporation to specifications established by NASA's Marshall Space Flight Center in Huntsville, Alabama. Appreciation is extended to MSFC for permission to publish this paper and for data and help provided for its preparation. -

"The toughest weld of all" S-II stage manufacturing.

Article explores the outer layer of the Saturn S-II along side its benefits and complications. Contains poorly rendered images displaying the process. -

"The significance of parameters affecting the heat transfer to the liquid hydrogen in the Saturn S-IVB stage for the lunar orbit rendezvous mission."

The Saturn S-IVB stage has a requirement for orbiting around the earth for up to 4.5 hours with approximately 60 percent of its initial propellant remaining at the end of the coast (prior to restart) . Extensive analyses must be performed to insure that this requirement is met. Both the maximum and minimum heat transfer rates are important because the maximum rates affect the hydrogen boiloff losses and thus the initial propellant loading requirements. The minimum rates are important because the boil off gases are used to maintain a minimum axial thrust level by venting the gases continuously through aft facing nozzles. This provides for a settling of the propellant throughout the orbital coast and alleviates the need for periodically venting the tank under zero gravity. -

"The Saturn V mission and Alabama."

Speech that covers the topics of the Saturn V lunar mission and the basics of a lunar mission in general. -

"The Saturn S-II."

The S-II is the second stage of NASA's Apollo moon-landing rocket - the giant Saturn V. The most powerful hydrogen-fueled booster under production, the S-II is destined for Apollo manned lunar missions and will help power three Americans to the moon. The S-II is being developed and manufactured at Seal Beach, Calif., by North American's Space and Information Systems Division, Downey, Calif., under the technical direction of NASA's Marshall Space Flight Center, Huntsville, Ala. -

"The Saturn launch vehicles."

General O'Connor's presentation to the American Institute of Aeronautics and Astronautics. Centers around saturn space vehicles and makes references to slides. -

"The Saturn launch vehicle family."

Presentation focusing on the history of Saturn V's engineering history and crew. -

"The role of weighing in the development and firing of missile and spaceships."

Speech regarding the importance of developing and upgrading space ships and space technology. -

"The role of the S-IVB in the Apollo and past Apollo programs."

Douglas Paper No. 4396.; Prepared by Ludwig Roth, Director, Saturn/Apollo Program Extension, Douglas Aircraft Company.; Presented to 16th Annual Conference of the Hermann Oberth Society. Discusses the role of the Apollo rocket after the Apollo program has concluded. -

"The role of the NASA-MSFC Manufacturing Engineering Laboratory in the development of space projects."

For presentation at the Aerospace Industries Association of America (AIA) Manufacturing Engineering Committee Meeting. Discusses the role the NASA Engineering Laboratory has had on NASA projects in the form of vehicles and smaller projects. -

"The role of simulation in the development of an automatic checkout system"

For publication in Luftfahrttechnik Raumfahrttechnik. Discusses the uses and advantages to using simulations. -

"The reliability picture at Marshall Space Flight Center - philosophy, staffing and management. Proposed talk to Orlando Section American Society for Quality Control."

Document that discusses the importance of reliability in engineering. -

"The reliability of the all-up concept."

Prepared for George C. Marshall Space Flight Center, Huntsville, Alabama under contract NAS8-11087. Publication No. 294-02-12-440. Special Technical Report No. 13.; INTRODUCTION: The Saturn/Apollo Systems Office at the George C. Marshall Space Flight Center (MSFC) requested ARINC Research Corporation to make a brief study of the reliability aspects of the All-Up concept. Under the requirements of Task 294-02 of Contract NAS8-11087, the study included a comparison between the reliability of the first Saturn V vehicle if All-Up, and its reliability with dummy upper stages. -

"The program manager's problem"

Included in "First Annual Logistics Management Symposium," Huntsville, Alabama; Archive copy is a poor photocopy. Describes the stages of rocket-development/launch and the logistical problems with each. -

"The production of large tanks for cryogenic fuels"

Archive copy is a poor photocopy. Prepared for presentation at Deutsche Gesellschaft fur Raketentechnik und Raumfahrt. (German Society for Rocket Technology and Astronautics). Given by E. Harpoothian, Chief Engineer, Structures Department, Development Engineering.; Tanks for cryogenic fluids, as used in the Saturn space vehicles, have reached an advanced stage of design and development. Many of the structural features of the NASA/Douglas Saturn tanks, fabricated of 2014-T6 aluminum alloy, were first developed for the booster of the Thor ballistic missile, which later found extensive use in putting space vehicles into orbit. There is a mutual dependence of important factors related to design concepts, selection of materials, processing techniques, and fabrication methods. It is shown that this mutual dependence must be considered if a successful vehicle is to emerge from design and development. Details of vehicle structure, provision for insulation, and manufacturing methods are presented. Criteria for the selection of materials is shown to be dependent on strength, ductility, weldability, toughness, fabricability, behavior at cryogenic temperatures, and on manufacturing methods and inspection techniques. -

"The potential bio-medical applications of Saturn nondestructive test methods."

A brief history and purpose of nondestructive methods followed by a discussion of those methods. -

"The NASA/Grumman Apollo lunar module"

Handwritten in pencil on the document. Describes the layout and function of various sections of the Apollo lunar module. -

"The J-2 Liquid Hydrogen Rocket Engine."

The 5-2 high-energy liquid propellant rocket engine (~i~. l), a large engine producing 200,000 pounds of thrust at altitude conditions, burns liquid hydrogen and liquid oxygen to produce the necessary high specific impulse for practical space use. Rocketdyne, a Division of North American Aviation, Inc., is developing the engine for the George C. Marshall Space Flight Center, Xfi. The first use of the engine will be in the upper stages of the Saturn vehicles. Five engines will be used for the second, S-I1 stage of the Saturn V, and one will power the S-IVB third stage of the Saturn V and S-ISTI second stage of 'the Saturn IB; Original is a photocopy on onion skin. -

"The Iterative Guidance Law for Saturn."

Summary: "Based on Lawden's equation, semi-explicit,'iterative' Saturn guidance equations are derived, many were successfully flight tested on Saturn I and analyzed for the main Apollo mission and other applications applications." -

"The instrumentation of space vehicle in connection with the successful Saturn flight tests."

Presented on September 21, 1962, at the Eleventh Tagung Der Deutchen Raketen - Gesellschaft, Koblenz, West Germany. Instrumentation sf the Saturn space vehicle represents a considerable effort during the development phase, for proper design evaluatian of this new configuration, its propulsion system, and its structure and control characteristics, an unprecedented number of measurements are required to be carried onboard and to be recovered, These measurements are expected to work properly and to furnish the design engineer with information that is not available by ground testing, -

"The Influence of Apollo/Saturn V Launch Operations on Lunar Site Selection: Case 330."

This paper presents some relationships between Apollo/Saturn V launch operations and multiple lunar landing sites, including the means by which site selection could facilitate launch operations. -

"The impact of manufacturing on design as related to accessibility."

The purpose of this paper is to emphasize the need for accessibility in the assembly and maintenance of spacecraft. This is especially pertinent because accessibility to subsystems for replacement, repair, and maintenance has proven to be one of the more costly phases of preflight preparation. The most successful programs in this day and age have been when the design and manufacturing engineers work side by side around a mockup where solutions to the problems can be visually seen and solved, keeping in mind the assembly as related to accessibility. Therefore, it will be shown that in order to overcome the difficulties, designers should adapt a hard, fast ground rule that each unit must be accessible and individually removable without disturbing the other units.; Aeronautic and Space Engineering and Manufacturing Meeting, Los Angeles, Calif. Oct. 7 - 11, 1968. -

"The IBM Clean Room Comes of Age."

A history of the IBM's Space Systems Center clean room and a description of its uses. -

"The history of Army missile development."

Published as "Army Missile Development," Army Information Digest, XI. Establishes the development and history of weaponized rocket ordenance. -

"The ease (E's) of implementation of the Safety Program at the Marshall Space Flight Center."

Presented at the 19th Annual Federal Safety Conference, National Safety Congress, Chicago, Illinois. A rundown of the new safety protocols, chiefly favoring the letter 'E.' -

"The development of the Saturn system safety program."

This paper describes the major highlights or milestones passed in the development of a System Safety Program at MSFC since early 1967. it discusses accomplishments, problems resolved, and decisions made for Apollo Saturn vehicles AS-501 and AS-502, and projects that are to be accomplished on future Saturn vehicles. -

"The Development of Servovalves with Improved Reliability for Space Vehicles."

Considerations for improvement in the reliability of the Saturn engine gimbal servosystems are briefly covered. The Saturn I servovalves operate with increased electrical input power. The Saturn V vehicle stages will use mechanical feedback actuators with increased electrical input power, larger orifices and nozzle sizes, larger torque motor wire size, and greater spool driving forces. -

"The development of a checkout language : ATOLL."

ATOLL was developed to fulfill the requirements for a common computer language that could be used by the test engineers for launch and factory checkout. "ATOLL" is the abbreviated name for Acceptance, Test, Or Launch Language. -

"The development of a bonded common bulkhead for Saturn."

A Part of the development of the Saturn S-IV/S-IVB stage the Douglas Aircraft Company has pioneered in the development of the cryogenic common bulkhead. The term common bulkhead is derived from the design function of the bulkhead, which is to separate the two cryogenics, liquid hydrogen and liquid oxygen, in a single tank, thereby shortening the stage and eliminating the necessity for two separate bulkheads and the associated interstage structure. The common bulkhead is structurally adequate to withstand both the thermal and the pressure loads from both the hydrogen and the oxygen tanks, and it has sufficient insulation properties to prevent the liquid hydrogen from freezing the liquid oxygen. Another benefit from the common bulkhead is that it permits a reduction in the total length of the vehicle, thereby reducing the bending moments. -

"The Common Bulkhead for the Saturn S-II Vehicle: Unique Manufacturing Effort Adds to Space-Age Hardware Technology".

Presentation regarding the construction of Apollo and Saturn rockets. -

"Test procedure validation by computer simulation."

Digital computer simulation of the Saturn I Instrument Unit electrical networks was accomplished using the Discrete Network Simulation programs. The schematics were analyzed and a logic model prepared which consisted of a series of Boolean equations. The test procedures, which are written in the Acceptance, Test, or Launch Language (ATOLL), consist of a sequential set of computer instructions for the RCA llOA checkout computer to control the operation of the electrical networks. The procedures also contain the predicted results for each operation. The driving functions for the simulation of the model are generated from the ATOLL test tape by the Input Generator Program. The time sequenced operation of the networks is indicatedby the output from the simulation program in addition to the number of times each component in the system changes state. The results of the simulation are compared to the test procedure predictions on the ATOLL tape by the Comparator Program and any differences are listed. The Comparator Program also lists any component which did not change state at least once. -

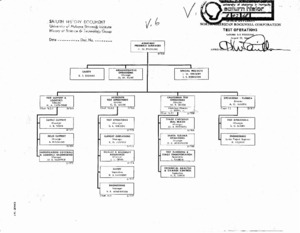

"Test operations:" Organization Chart.

Organization Chart of the North American Rockwell Test Operations.