Browse Items (716 total)

Sort by:

-

"The toughest weld of all" S-II stage manufacturing.

Article explores the outer layer of the Saturn S-II along side its benefits and complications. Contains poorly rendered images displaying the process. -

"The role of simulation in the development of an automatic checkout system"

For publication in Luftfahrttechnik Raumfahrttechnik. Discusses the uses and advantages to using simulations. -

"Thermal models of Jupiter and Saturn"

One of the orange Aid Preprint Series in Nuclear Astrophysics by W. B. Hubbard, California Institute of Technology, Pasadena, California.; Argues that the Saturnian models are flawed as their predictions do not line up with detected gravitational events. -

"The production of large tanks for cryogenic fuels"

Archive copy is a poor photocopy. Prepared for presentation at Deutsche Gesellschaft fur Raketentechnik und Raumfahrt. (German Society for Rocket Technology and Astronautics). Given by E. Harpoothian, Chief Engineer, Structures Department, Development Engineering.; Tanks for cryogenic fluids, as used in the Saturn space vehicles, have reached an advanced stage of design and development. Many of the structural features of the NASA/Douglas Saturn tanks, fabricated of 2014-T6 aluminum alloy, were first developed for the booster of the Thor ballistic missile, which later found extensive use in putting space vehicles into orbit. There is a mutual dependence of important factors related to design concepts, selection of materials, processing techniques, and fabrication methods. It is shown that this mutual dependence must be considered if a successful vehicle is to emerge from design and development. Details of vehicle structure, provision for insulation, and manufacturing methods are presented. Criteria for the selection of materials is shown to be dependent on strength, ductility, weldability, toughness, fabricability, behavior at cryogenic temperatures, and on manufacturing methods and inspection techniques. -

"The program manager's problem"

Included in "First Annual Logistics Management Symposium," Huntsville, Alabama; Archive copy is a poor photocopy. Describes the stages of rocket-development/launch and the logistical problems with each. -

Theoretical liquid propellant performance calculations

Archive copy is a photocopy.; The purpose of these writings is to compile in one volume the basic elements of thermodynamics and gas dynamics which are useful in the evaluation of thrust chamber performance. It is presumed that the reader will have had an elementary course in thermodynamics and gas dynamics. The discussion of topics useful in evaluating thrust chamber performance is, of necessity, limited to these physical effects amenable to other areas that are as yet in the research stage of development. The author would like to take this opportunity to express his gratitude to Mr. G. S. Gill for many stimulating discussions on this subject. Thanks are due to Mr. D. J. Kuyper for permission to utilize his discussion on elastic-plastic strain and its application to nozzle throat area change. Finally, the author wishes to express his gratitude to his wife, Alice, who typed the bulk of the manuscript. -

"The NASA/Grumman Apollo lunar module"

Handwritten in pencil on the document. Describes the layout and function of various sections of the Apollo lunar module. -

"The history of Army missile development."

Published as "Army Missile Development," Army Information Digest, XI. Establishes the development and history of weaponized rocket ordenance. -

"The ease (E's) of implementation of the Safety Program at the Marshall Space Flight Center."

Presented at the 19th Annual Federal Safety Conference, National Safety Congress, Chicago, Illinois. A rundown of the new safety protocols, chiefly favoring the letter 'E.' -

"The development of a bonded common bulkhead for Saturn."

A Part of the development of the Saturn S-IV/S-IVB stage the Douglas Aircraft Company has pioneered in the development of the cryogenic common bulkhead. The term common bulkhead is derived from the design function of the bulkhead, which is to separate the two cryogenics, liquid hydrogen and liquid oxygen, in a single tank, thereby shortening the stage and eliminating the necessity for two separate bulkheads and the associated interstage structure. The common bulkhead is structurally adequate to withstand both the thermal and the pressure loads from both the hydrogen and the oxygen tanks, and it has sufficient insulation properties to prevent the liquid hydrogen from freezing the liquid oxygen. Another benefit from the common bulkhead is that it permits a reduction in the total length of the vehicle, thereby reducing the bending moments. -

"The development of a checkout language : ATOLL."

ATOLL was developed to fulfill the requirements for a common computer language that could be used by the test engineers for launch and factory checkout. "ATOLL" is the abbreviated name for Acceptance, Test, Or Launch Language. -

"Test procedure validation by computer simulation."

Digital computer simulation of the Saturn I Instrument Unit electrical networks was accomplished using the Discrete Network Simulation programs. The schematics were analyzed and a logic model prepared which consisted of a series of Boolean equations. The test procedures, which are written in the Acceptance, Test, or Launch Language (ATOLL), consist of a sequential set of computer instructions for the RCA llOA checkout computer to control the operation of the electrical networks. The procedures also contain the predicted results for each operation. The driving functions for the simulation of the model are generated from the ATOLL test tape by the Input Generator Program. The time sequenced operation of the networks is indicatedby the output from the simulation program in addition to the number of times each component in the system changes state. The results of the simulation are compared to the test procedure predictions on the ATOLL tape by the Comparator Program and any differences are listed. The Comparator Program also lists any component which did not change state at least once. -

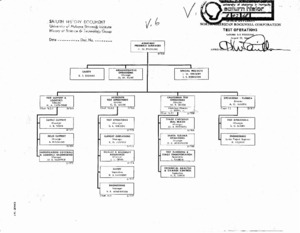

"Test operations:" Organization Chart.

Organization Chart of the North American Rockwell Test Operations. -

"Test Laboratory monthly progress report" October.

Laboratory monthly progress report for the Saturn 1B program between dates October 1st through October 31st, 1967. Page 17 missing. -

"Test Laboratory monthly progress report" December.

Laboratory monthly progress report for the Saturn 1B program between dates December 1st through December 31st, 1967. -

"Test Laboratory monthly progress report" July.

Laboratory monthly progress report for the Saturn 1B program between dates July 1st through July 31st, 1967. -

"Test Laboratory monthly progress report" August.

Laboratory monthly progress report for the Saturn 1B program between dates August 1st through August 31st, 1967. -

"Test Laboratory progress report" May and June.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between Feburary and March -

"Test Laboratory progress report" Febuary and March.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between Feburary and March -

"Test Laboratory monthly progress report" Febuary.

Laboratory monthly progress report for the Saturn 1B program between dates Febuary 1st through Febuary 31st, 1967. -

"Test Laboratory monthly progress report" April.

Laboratory monthly progress report for the Saturn 1B program between dates April 1st through April 31st, 1967. Last page of document is missing. -

"Test Laboratory monthly progress report" June.

Laboratory monthly progress report for the Saturn 1B program between dates June 1st through June 31st, 1967. -

"Test Laboratory monthly progress report" September.

Laboratory monthly progress report for the Saturn 1B program between dates September 1st through September 31st, 1967. -

"Test Laboratory monthly progress report" January.

Laboratory monthly progress report for the Saturn 1B program between dates January 1st through January 31st, 1968. -

"Test Laboratory progress report" March and April.

Monthly rogress report for the test laboratory regarding the Saturn 1B program between March and April. -

"Telemetry system design for Saturn vehicles."

This paper discusses the data system requirements for large space vehicles and describes a flexible telemetry system design which is used on all stages of the Saturn IB and Saturn V vehicles. The basic vehicle telemetry design provides standard assembly building blocks forming a versatile catalogue of parts from which a stage telemetry subsystem may be assembled to meet almost any conceivable monitoring requirement. In addition to its inflight monitoring function, the telemetry subsystem also provides real time data acquisition for automatic vehicle checkout. -

"Telegraphic message : inspection requirements for S-II-1 and S-II-2 at KSC."

Photocopy of an inspection list requirements for S-II-1 and S-II-2. -

"Telemetry system for Saturn S-I stage development."

The telemetry system used on the Saturn S-I stage for the transmission of vehicle test data is described. Multiplex and modulationtechniques such as PAM/FM/FM, SS/FM and PGM are used in the system. The diverse data requirements for developing the eight-engineliquid-fueled stage necessitated the use of a combination of severalmodulation techniques to efficiently handle the data. A cursory comparisonis made of the merits of each technique. Physical and electricalrequirements and characteristics of the system are outlined. -

"George C. Marshall Space Flight Center Mississippi Test Facility Telephone directory 1965."

Telephone directory belonging to the George C. Marshal Space Flight Center Mississippi Test Facility for October 1965. -

"George C. Marshall Space Flight Center Mississippi Test Facility Telephone directory 1968."

Telephone directory belonging to the George C. Marshal Space Flight Center Mississippi Test Facility for 1968. -

"Technical survey of ABMA activities."

Handwritten notes on the document.; Archive copy is a poor photocopy. -

Technical Reports" Bibliography.

Bibliography of technical reports from 1957-1963 -

"Technological problems of the Saturn class vehicle."

Aerospace Workshop. University of Hawaii.; Includes references to slides. -

"Technical problems in on-board checkout systems."

For the purposes of this paper, an onboard checkout system is defined as a system which is built into prime flight equipment, flies with it, and permits a checkout capability to exist during all the major phases of the test and mission life of that prime equipment. Varying degrees of capability may exist in such a system, depending on what is designed into it. This, in turn, is generally dependant on life and mission requirements of the prime equipment, degree of mission checkout required, reliability restrictions,redundancy levels, data management scheme, and equally important, state of the art . Not all checkout can be accomplished with onboard equipment. Mechanical system problems such as leak detection, for example, require techniques that cannot be remotely controlled and evaluated today. On the other hand, such things as in-flight telemetry have been used for quite a long time and will continue to be used for onboard checkout. -

"Technique for reliability circuit design review in space electronics."

Design review is becoming a basic requirement during the design and development of military systems. The main purpose of the design review is to increase the system's inherent and operational reliability. The major portion of this paper is the result of reliability's effort to comply with Paragraph 3.6 of NPC 250-1 Reliability Program Provisions for Space Contractors. The design review to be discussed is a reliability circuit design review with emphasis placed on what should be reviewed and the review techniques employed. The basic circuit design review prerequisites, component parts and their ratings, are discussed at the beginning of this paper. The remainder deals with the organization and reviewing of circuits. The review items include worst-case circuit performance, component applications, failure mode analysis, noise rejection, electrical stress, and the determination of component temperatures. Many examples are included to illustrate how each item was accomplished. This paper is intended not only to give the reliability analyst cognizance of basic design problems and troublesome circuits, but also, to aid him in formulating a design review program. -

"Technician inspects an RL10 liquid hydrogen engine."

A technician inspects an RLlO liquid hydrogen rocket engine OD the assembly floor. of Pratt & Whitney Aircraft's Florida Research and Development Center. The 115,000-pound-thrust RLlO was designed and developed for the National Aeronautics and Space Administration's Saturn S-IV azld Centaur space vehicles. -

"Technical information summary concerning Saturn vehicle SA-3."

This memorandum outlines, through a series of sketches, some of the important features and sequences concerning the third SATURN flight vehicle. The sketches are devoted primarily to the control and instrumentation aspects of the vehicle but also touch on the launch facility and countdown schedule. -

"Technical information summary concerning Saturn vehicle SA-3."

This memorandum outlines, through a series of sketches, some of the important features and sequences concerning the third SATURN flight vehicle. The sketches are devoted primarily to the control and instrumentation aspects of the vehicle but also touch on the launch facility and countdown schedule. -

"Technical Information Summary Apollo-9 (AS-504) Apollo Saturn V Space Vehicle."

The document presents a brief and concise description of the Apollo 9 Saturn Space Vehicle. -

"Technical information summary Apollo-10 (AS-505) Apollo Saturn V space vehicle."

The document presents a brief and concise description of the AS-505 Apollo Saturn Space Vehicle. Where necessary, for clarification, additional related information has been included.